Product name: Tunnel Oven

|

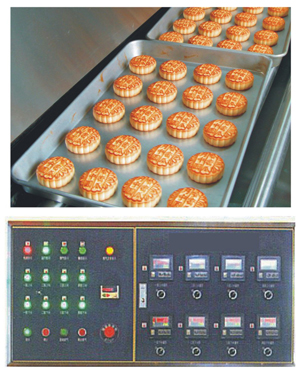

Oven system not only can save manpower, but also meet continuous operation requirements of the industrialized mass production. Basic dimensions: Length: 3000mm A height: 1500mm (not include the control box) Width: 2050mm Furnace size: 1400mmx 170mm Standard tray: 400*600mm Standard way: double-disc horizantally Oven system 1、JIUYI not only meets higher requirements of oven,but also has full understanding about manufacture of the bread and cakes production,we are ready for making new design and development according to your requirements. 2、Adopt clean energy, such as electric, industry gas, natural gas. And accord with energy changeable requirements, furthermore, with more efficient heating effect. 3、All coin has two sides, for the oven, we kindly suggest to choose them as per your special requirements. |

|

| Electronic control box | Manual lighter | Gas detection alarm device |

Manual lighter | 2 times the pressure regulating system | Manual ignition device | Gas detection alarm device | Manual ignition device |

|

|||||||

|

||

| High quality cotton(CSR-120kg3/m3) | Real aluminum plate(GB 1.5mm) |

3mm flat really screw and chain plate. (With punching, energy-efficient) |

|

Gas security and protection system 1、Please well note that all the gas should be filtered before entering into the tunnel oven. As the fine filter''''s can ensure the fire tube''''s gas burned well. 2、 If the fuel gas pressure is too high or too low, Main air valve will cut off automatically, ,and branch electromagnetic valve will delay switch off. 3、The main inlet control valve of the running pipe will adjust the outlet pressure automatically.Which ensure the gas pressure conforming with tunnel oven''''s. 4、Before ignition, the inner oven should pump the air by force, and make full gas purification.Faulty ignition is with the function of automatic inspection and alarm system also. 5、introducing automatic and manual emergency handing systems.The automatic inspection and alarm system will give an alarm and cut off the Electromagnetic valve while the gas inside oven exceed the standard. And the -oven will make a delaying stop make sure all bread and cake roasting well. 6、New secondary pressure regulating system, more security than decompression one time, easier to control. 7、All the data can be changed to the images according to the customer''''s requirements and realize man-machine dialogue. |

|

Workshop

The same series products

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven

Tunnel Oven